Twin Welding Hose|Industrial High-Pressure Twin Hose

Meta Description

Twin welding hose meets ISO 3821 standards, supports 20-bar pressure, abrasion-resistant, flexible design, ideal for welding and blasting, a reliable industrial tool.

Twin Welding Hose - Detailed Analysis

The twin welding hose is a high-performance, multi-purpose industrial hose designed for welding and blasting operations. Made with premium materials and advanced craftsmanship, this hose delivers excellent durability, flexibility, and safety to meet the stringent demands of industrial applications.

Material and Structural Features

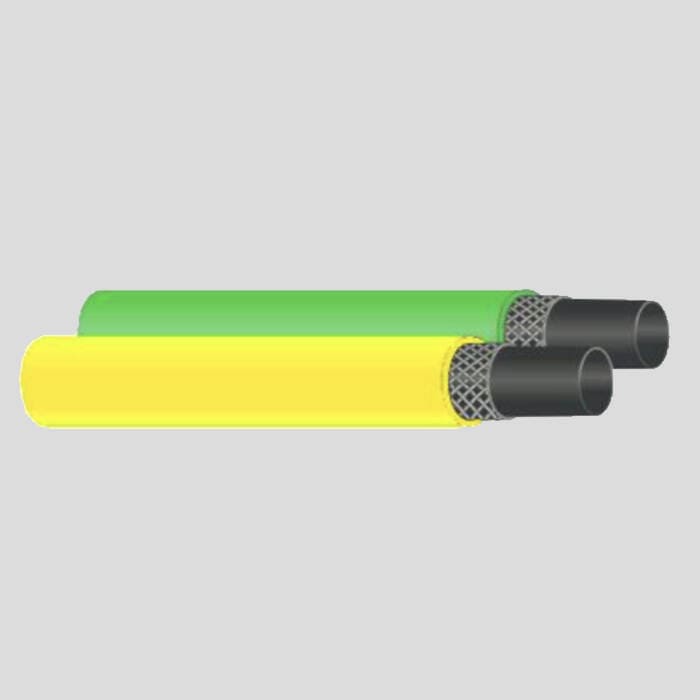

The inner layer is made of black natural rubber (NR) and styrene-butadiene rubber (SBR), offering outstanding abrasion resistance and chemical stability. The outer layer uses green and yellow NR/SBR material, enhancing abrasion resistance and providing color-coded differentiation for added operational safety. The high-strength fiber fabric reinforcement layer allows the hose to withstand a working pressure of 20 bar, maintaining structural integrity under high-pressure conditions and preventing leaks or ruptures.

Performance and Technical Advantages

The twin welding hose operates efficiently within a temperature range of -20°C to +70°C, making it suitable for extreme environments. Whether for outdoor use in cold conditions or high-temperature welding, it provides reliable performance. With a safety factor of 3:1, the hose ensures secure operation even under overpressure conditions. Its flexible design adapts easily to narrow or complex workspaces, improving arrangement efficiency and reducing operational challenges.

Design Highlights

The green and yellow outer layers make it easy to identify the hose’s functions during operations, preventing errors. The twin-hose design allows simultaneous transmission of gas and fuel, significantly increasing efficiency in welding and cutting tasks. Standard coil configurations simplify installation and maintenance, enhancing user experience.

Applications

The twin welding hose is ideal for oxygen and acetylene welding and cutting operations, making it a perfect choice for industrial welding. It is also suitable for gas transfer in blasting operations, providing reliable performance even in harsh environments. Its versatility makes it highly valuable in manufacturing, construction, and other industries requiring synchronized gas transmission.

Technical Specifications

Inner material: Black NR/SBR, offering abrasion and corrosion resistance

Reinforcement: High-strength fiber fabric for superior pressure resistance

Outer material: Green/yellow NR/SBR, abrasion-resistant with functional differentiation

Temperature range: -20°C to +70°C, meeting industrial needs

Safety factor: 3:1, ensuring secure and reliable operation

Frequently Asked Questions (FAQ)

Q: What are the main uses of the twin welding hose

A: It is primarily used for safe transmission of oxygen and acetylene, suitable for welding, cutting, and blasting tasks.

Q: What is the working pressure of the hose

A: The maximum working pressure is 20 bar, sufficient for most industrial environments.

Q: How should the hose be stored to extend its lifespan

A: Store the hose in a dry, shaded environment, avoiding direct sunlight and extreme temperatures.

Q: What are the advantages of the twin-hose design

A: The twin-hose design enables simultaneous transmission of multiple media, increasing efficiency and reducing setup time.

Q: Can the hose specifications be customized

A: Yes, customization options are available for various lengths and configurations to meet specific requirements.

Maintenance and Care Suggestions

Avoid contact with sharp objects during use to prevent damage to the outer layer. After use, clean the outer surface with water or a suitable cleaner to prevent dust and grease buildup. Regularly inspect the hose for cracks or wear, and replace any damaged parts immediately. During storage, keep the hose in a dry, shaded area and avoid excessive bending to extend its lifespan.

Conclusion

The twin welding hose combines high-quality materials, precise craftsmanship, and outstanding performance to become an essential tool for industrial welding and blasting operations. Its high strength, flexible design, and reliability enhance operational efficiency and ensure workplace safety, making it a perfect choice for industrial applications.