Detailed Explanation of Rubber Bushings

Rubber bushings are common industrial and mechanical components widely used for damping, vibration isolation, and protecting connections between parts. With excellent elasticity, wear resistance, and vibration isolation properties, they have become indispensable in many machines and equipment. Below is a detailed explanation of rubber bushings in terms of structure, characteristics, applications, and advantages.

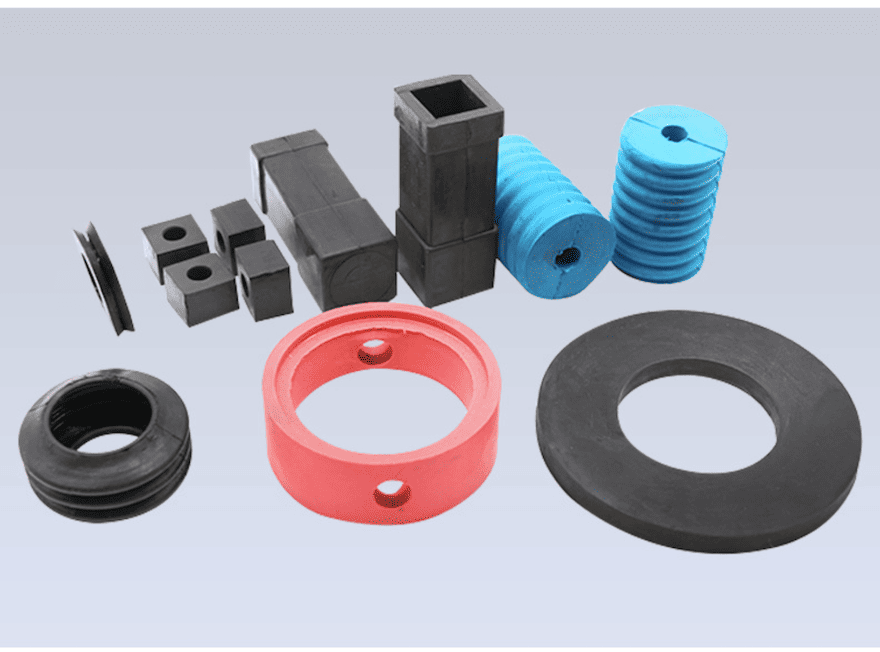

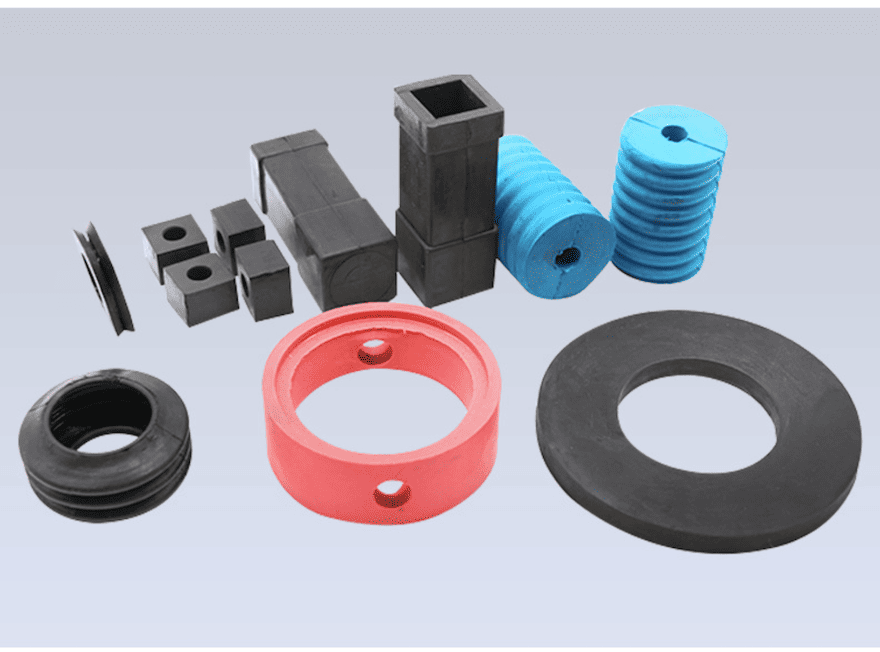

1. Structure of Rubber Bushings

Rubber bushings typically consist of an outer metal sleeve, an inner rubber layer, and an inner metal sleeve. The inner rubber layer plays a critical role in absorbing shocks and vibrations, while the outer metal sleeve or inner metal sleeve provides installation and stability. Depending on specific needs, rubber bushings can be designed with varying thicknesses, hardness levels, and sizes to suit different working conditions.

2. Key Characteristics

1.Excellent Shock Absorption:

Rubber bushings leverage the high elasticity of rubber to effectively absorb mechanical vibrations, reducing the impact on equipment.

2.Good Vibration Isolation:

The vibration isolation properties of rubber minimize the transmission of noise and vibrations, improving operational stability and comfort.

3.Wear and Fatigue Resistance:

High-quality rubber materials provide outstanding wear resistance, extending the service life of bushings and reducing replacement costs.

4.Aging Resistance:

Treated with specific formulations, rubber bushings offer excellent aging resistance, making them suitable for long-term use in harsh environments.

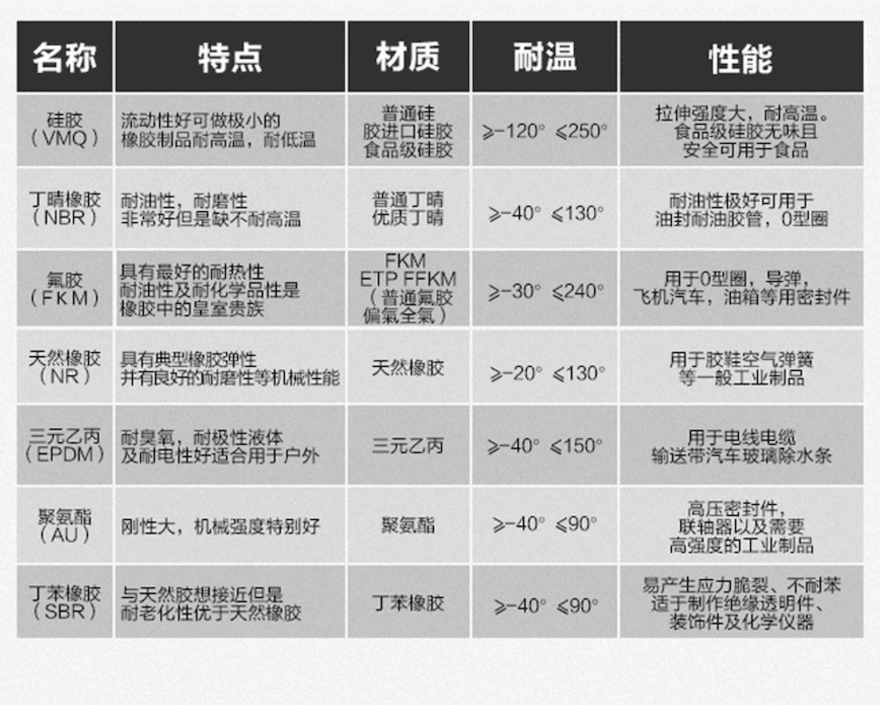

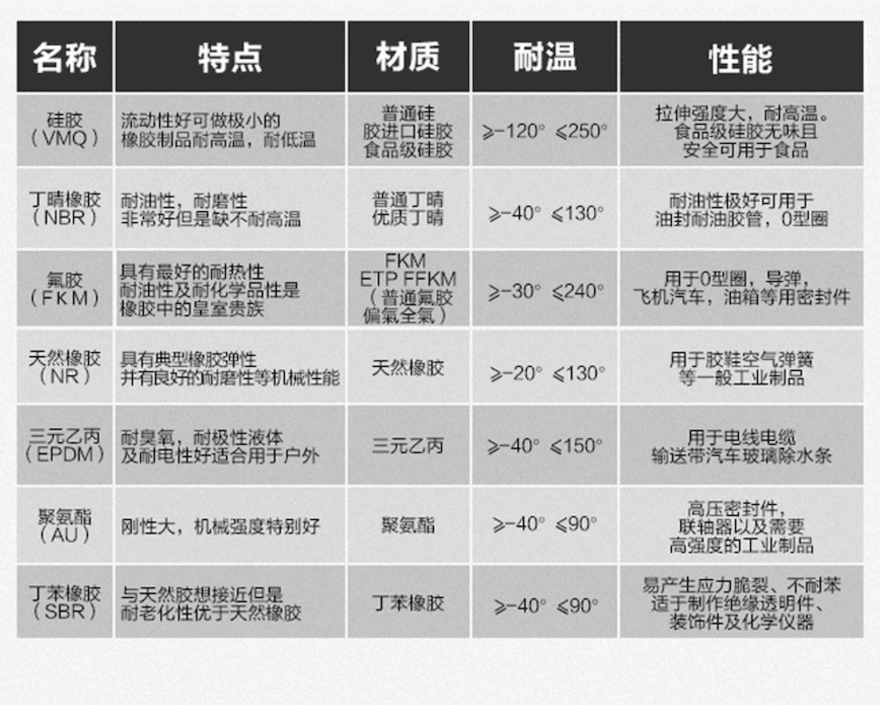

5.Chemical Resistance:

They resist oils, fuels, acids, alkalis, and other chemicals, making them ideal for chemically complex environments.

3. Application Areas

1.Automotive Industry:

Rubber bushings are extensively used in suspension systems, engine mounts, and transmission systems to mitigate shocks and vibrations between vehicle components, enhancing driving comfort.

2.Construction Machinery:

In excavators, loaders, and other construction equipment, rubber bushings protect critical components, extend equipment life, and improve operational efficiency.

3.Industrial Equipment:

They are used in vibration control for machines such as pumps, compressors, and motors, ensuring the stability of connected components.

4.Construction Sector:

Rubber bushings reduce mechanical noise and vibration in construction equipment, minimizing environmental impact during construction.

5.Home Appliances:

In household appliances like washing machines and air conditioners, rubber bushings effectively reduce operational noise and enhance user experience.

4. Product Advantages

1.Versatility:

Rubber bushings combine damping, vibration isolation, and sealing functions to meet various application needs.

2.Cost-Effectiveness:

Compared to other damping materials, rubber bushings are more affordable while offering superior performance.

3.Flexibility:

They can be customized in different sizes, shapes, and hardness levels to suit complex working environments.

4.Environmental Friendliness:

Some rubber bushings are made from recyclable materials, aligning with modern environmental standards.

5. Future Development Trends

With the advancement of industries and technology, rubber bushings continue to improve in material innovation and design optimization. For example, new high-performance rubber materials are being developed to enhance their resistance to high temperatures, chemicals, and fatigue. Additionally, automation in production processes will further reduce costs and improve product quality and market competitiveness.

Conclusion

Rubber bushings are efficient, multifunctional components for damping and protection, widely used in industrial, automotive, and construction sectors. Their excellent performance and cost-effectiveness make them an ideal solution for vibration issues. In the future, through technological innovations and material improvements, rubber bushings will continue to provide more comprehensive support for mechanical equipment and everyday life.