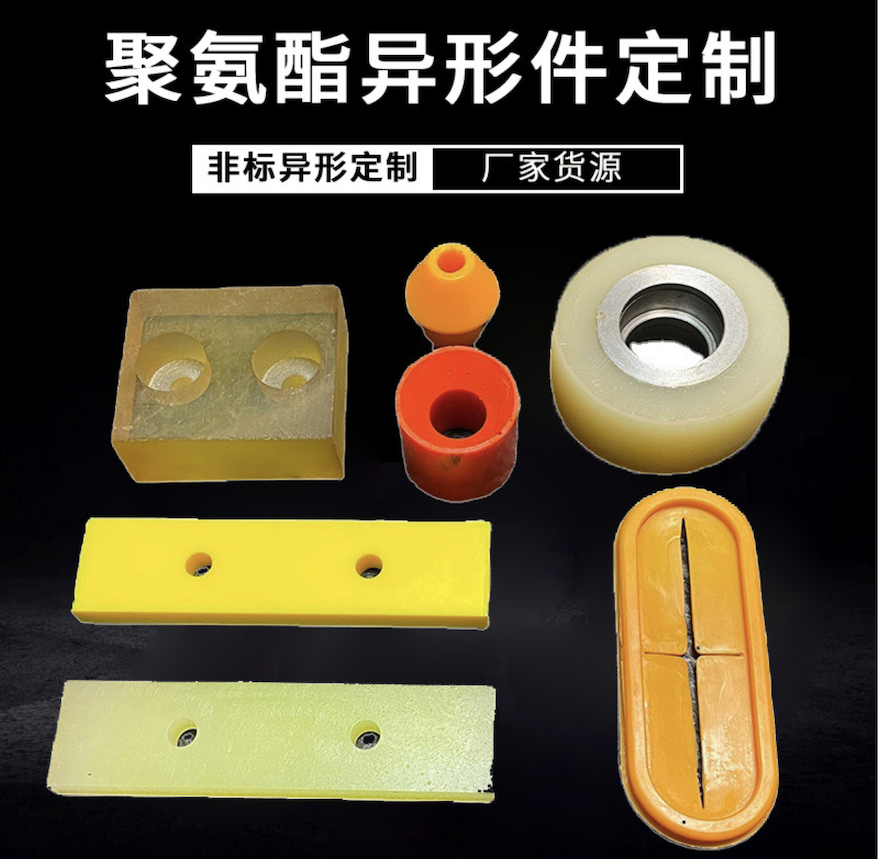

Detailed Description of Polyurethane Gaskets

Polyurethane gaskets are versatile sealing materials widely used in industries and daily life. With excellent physical and chemical properties, they are essential components in many fields. Below is a detailed explanation of the features, applications, advantages, and working principles of polyurethane gaskets.

1. Material Characteristics

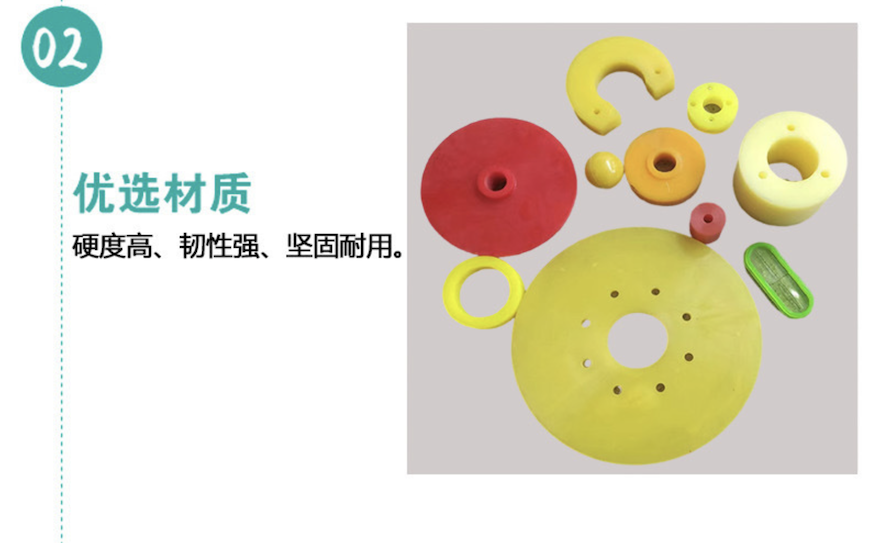

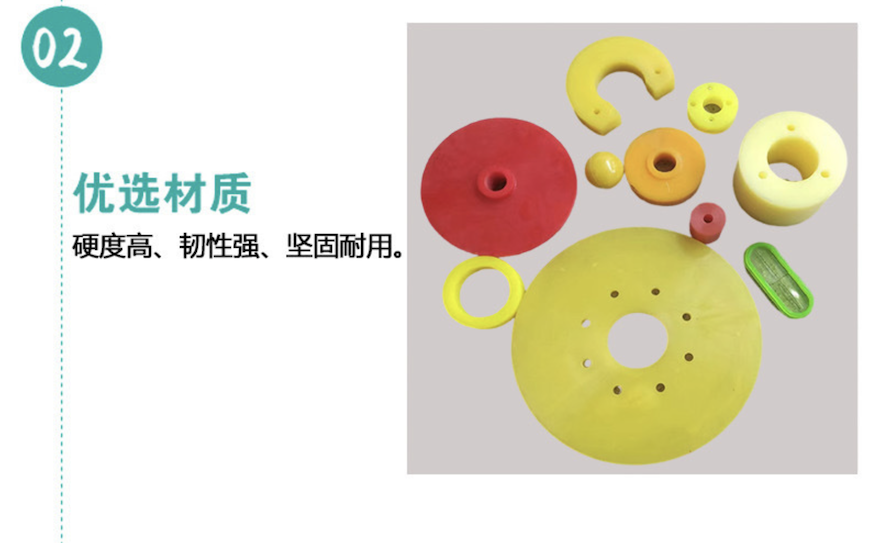

Polyurethane gaskets are made from polyurethane, a polymer material known for its outstanding mechanical properties and chemical stability. Key characteristics include:

1.High Elasticity: Polyurethane gaskets offer excellent elasticity and flexibility, maintaining their shape under high pressure or deformation.

2.Superior Wear Resistance: The high wear resistance of polyurethane makes it suitable for applications involving friction or repeated use.

3.Chemical Resistance: They resist oils, fuels, solvents, and other chemicals, making them ideal for complex chemical environments.

4.Wide Temperature Adaptability: They perform stably across a broad temperature range, from -40°C to +100°C or higher.

5.High Strength: They exhibit excellent tensile, tear, and shear strength, meeting the demands of harsh conditions.

2. Working Principles

The primary functions of polyurethane gaskets are sealing, isolation, or cushioning. Their elasticity and density allow them to form an effective seal between contact surfaces, preventing the leakage of liquids, gases, or particles. Additionally, their wear resistance and compression-set resistance significantly extend their service life.

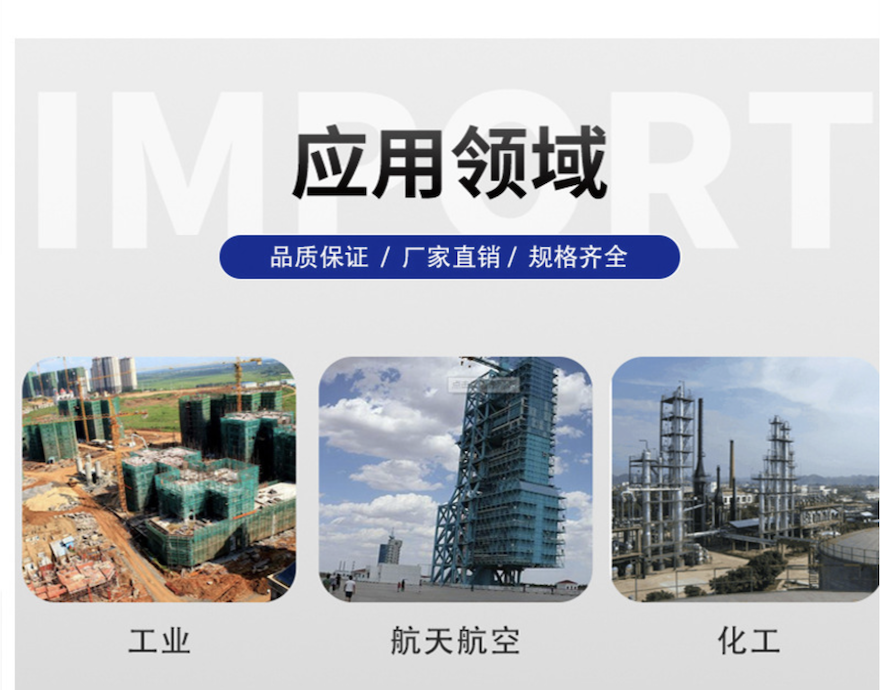

3. Applications

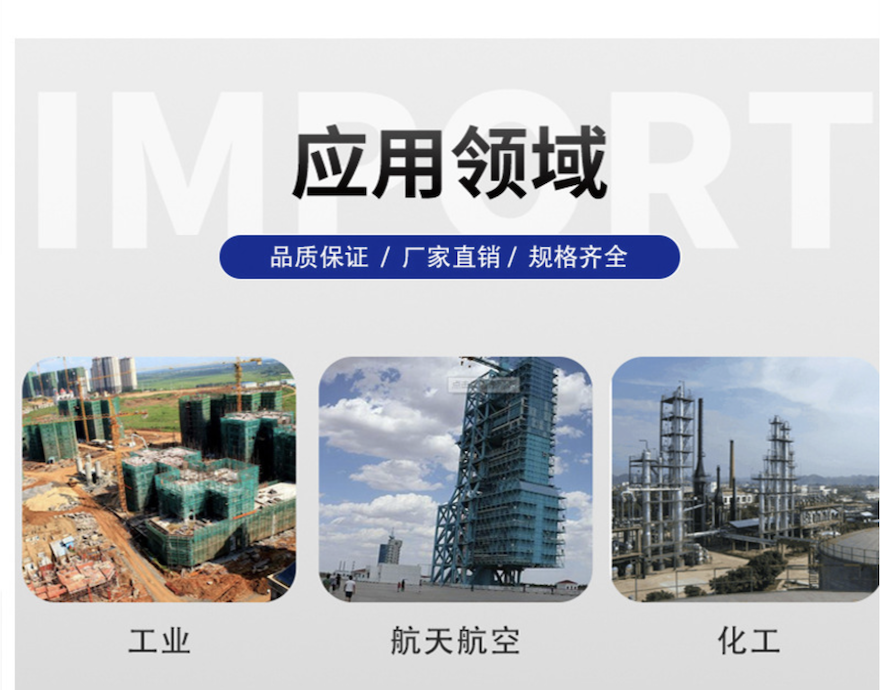

Polyurethane gaskets are used in various industries and scenarios, including:

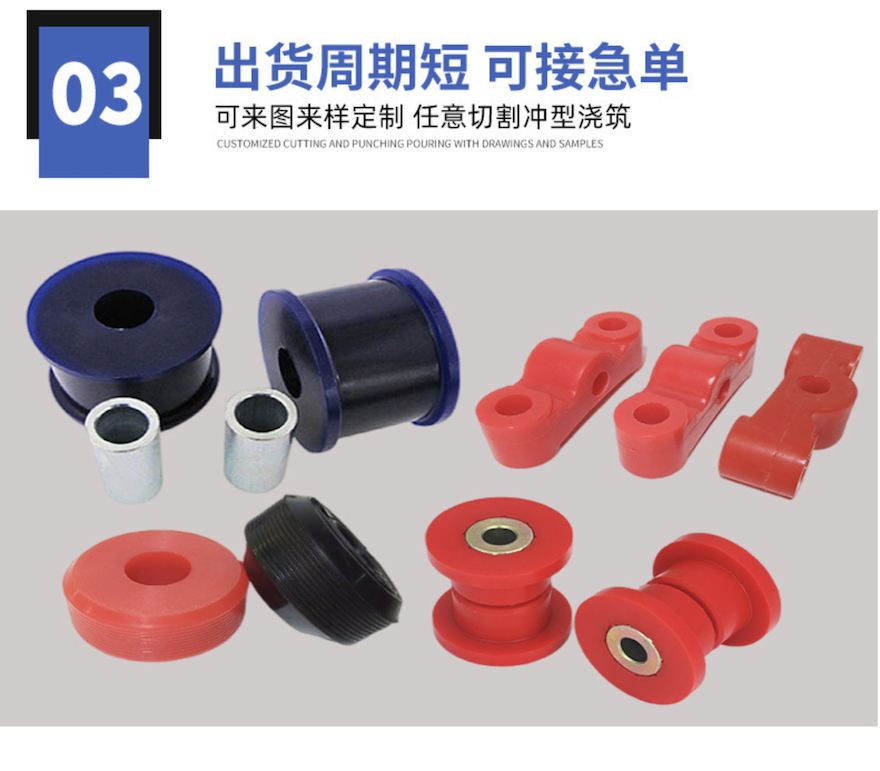

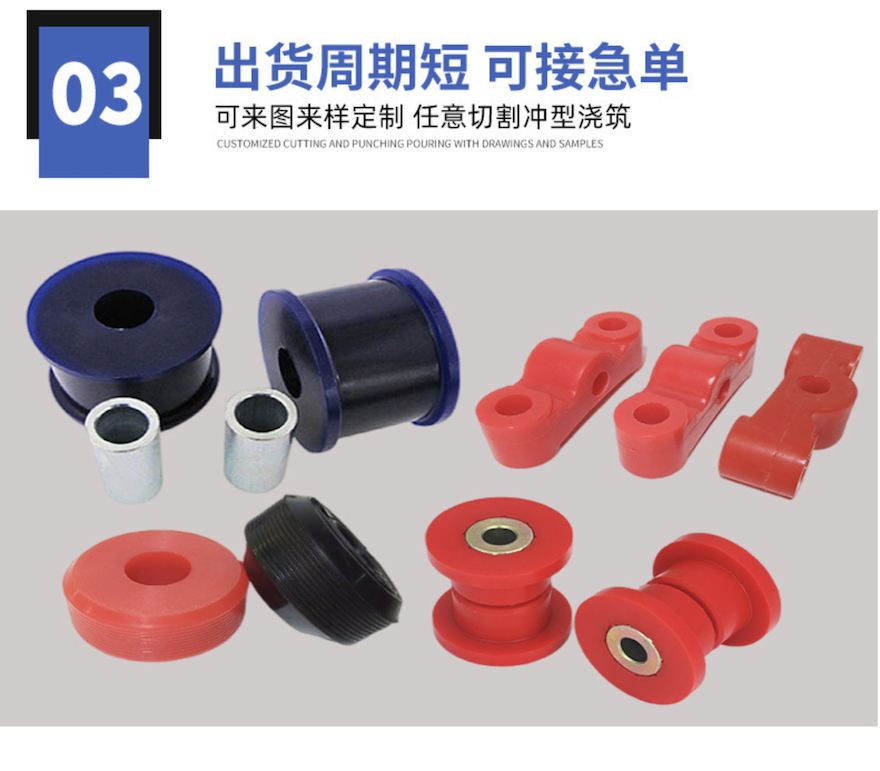

1.Mechanical Sealing: Used as seals in hydraulic and pneumatic systems to ensure efficient fluid system operations.

2.Automotive Industry: Applied in engines, transmission systems, and brake systems for reliable sealing performance.

3.Construction: Used for sealing in doors, windows, and waterproofing systems to prevent air or water infiltration.

4.Electronics and Electrical: Used for insulation or shock absorption in devices, protecting critical components from damage.

5.Food Industry: Certain polyurethane gaskets meet food-grade standards and are used in food processing equipment.

6.Medical Sector: Applied as seals in medical equipment to ensure sterility and safety.

4. Product Advantages

1.High Performance: Polyurethane gaskets offer a combination of properties that meet the requirements of complex working conditions.

2.Durability: Compared to traditional sealing materials, polyurethane gaskets have a longer service life, reducing replacement frequency and maintenance costs.

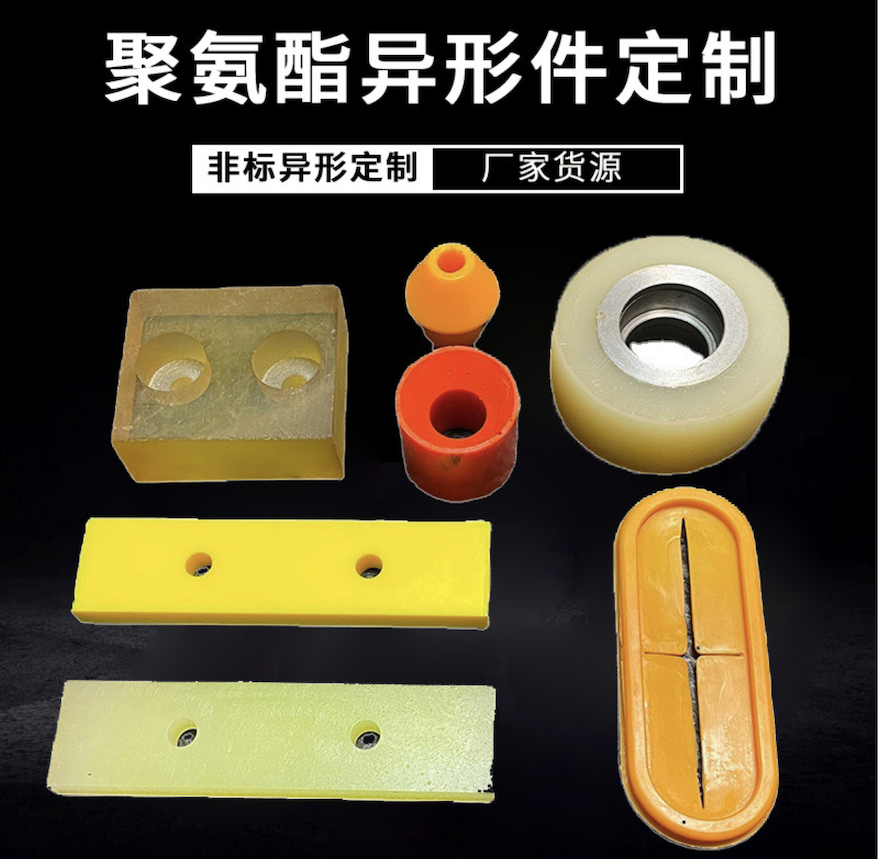

3.Customization: Available in different hardness, densities, thicknesses, and colors to meet specific customer needs.

4.Environmentally Friendly: Some products comply with environmental and non-toxic standards, making them suitable for high-standard industries.

5.Cost-Effective: While ensuring high quality, polyurethane gaskets are relatively low-cost, providing excellent value for money.

5. Environmental and Future Developments

As environmental standards become increasingly stringent, the production and design of polyurethane gaskets are shifting toward greener, more sustainable solutions. This includes using renewable materials and reducing harmful chemicals. Additionally, with technological advancements, polyurethane gaskets are expected to achieve even better performance to meet more complex application scenarios.

Conclusion

Polyurethane gaskets are high-performance, multifunctional, and durable sealing materials. Their superior properties and wide range of applications make them indispensable in many industries. Their flexibility, high performance, and cost-effectiveness make them ideal for addressing sealing challenges. In the future, with innovation and environmentally friendly improvements, polyurethane gaskets will provide more comprehensive support for industrial and everyday needs.