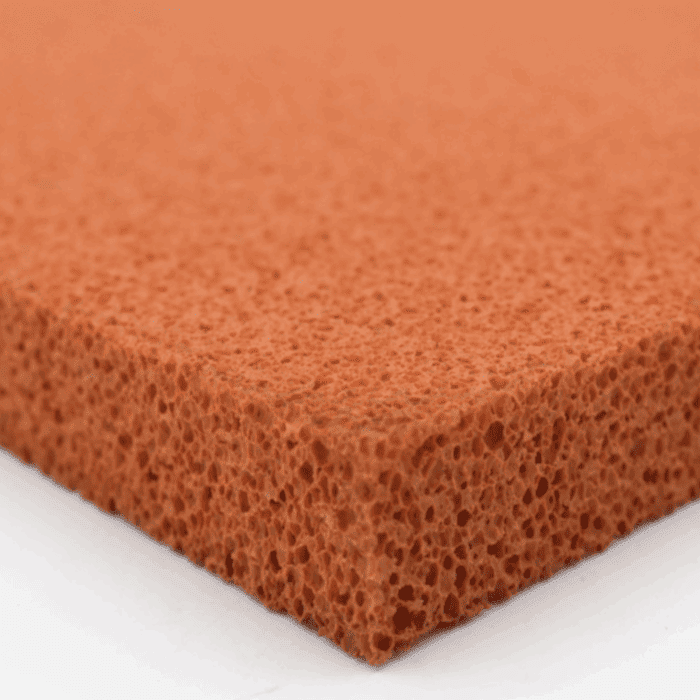

Orange Open Cell Sponge: High-Performance Packaging and Soundproofing Solution

Overview

Orange open cell sponge is a high-quality and eco-friendly material widely used across various industries. With its excellent water absorption, wear resistance, elasticity, and flexibility, this sponge is ideal for applications in packaging, transportation, soundproofing, and other industrial uses. The main component of the sponge is natural rubber, which gives it superior physical properties. Its open-cell structure not only provides excellent water absorption but also helps it withstand humid environments and high temperatures.

Material Features and Advantages

Made from High-Quality Natural Rubber

Orange open cell sponge is made from natural rubber, providing it with excellent elasticity and wear resistance. The unique properties of natural rubber give the sponge high heat resistance and compressive strength, allowing it to maintain stability in harsh environments.

High-Temperature Performance

This sponge maintains good stability in high-temperature environments, up to 80°C, making it suitable for high-temperature sealing and protective applications.

Elasticity and Flexibility

Orange open cell sponge has elasticity up to 40°C, allowing it to adapt to various sealing needs in complex environments. Its softness and flexibility allow it to tightly fit irregular surfaces, meeting the requirements of various application scenarios.

Excellent Wear Resistance

Thanks to the physical properties of natural rubber, the sponge has strong wear resistance, withstanding friction and pressure from long-term use without easily deforming or breaking down.

Strong Water Absorption

The open-cell structure of the sponge enables it to effectively absorb water in humid environments, preventing liquid spread. This water-absorbing capability is crucial in packaging and transportation, especially in preventing liquid spillage.

FDA Compliance

The material complies with FDA 21 CFR 177.2600 standards, making it safe for food contact applications, ensuring its suitability for use in the food industry.

Multiple Density Options

Orange open cell sponge is available in densities ranging from 160 to 500 kg/m³, catering to different application needs. Selecting the appropriate density is essential to ensure optimal performance in various working environments.

Multiple Forms Available

In addition to standard sponge sheets, orange open cell sponge can be customized into forms such as gaskets, strips, rolls, seals, and discs to meet the specific needs of different applications.

Excellent Ozone Resistance

This material has excellent ozone resistance, making it suitable for long-term use in outdoor and harsh environments. It is ideal for applications such as outdoor sealing, closure, and protection.

Wide Range of Applications

Orange open cell sponge’s excellent physical properties make it essential in multiple industries. Below are some typical applications across various sectors:

Packaging and Transportation

Orange open cell sponge is widely used in packaging and transportation, especially for delicate and fragile items. Its superior water absorption, cushioning performance, and lightweight nature make it an ideal protective material, preventing damage from moisture, friction, or collisions during transport.

Vacuum Lifting Seals

The sponge is commonly used as a sealing component in vacuum lifting systems. Its high elasticity and sealing capability enable it to adapt well to various surfaces, ensuring effective sealing in vacuum environments and preventing leaks or air intrusion.

Physical Therapy and Rehabilitation Equipment

Due to its high elasticity and comfort, orange open cell sponge is widely used in physical therapy and rehabilitation equipment, such as massage pads and therapy mats. Its soft texture provides a comfortable experience and supports body recovery.

Interior Decoration and Textile Manufacturing

In interior decoration and textile manufacturing, orange open cell sponge is used as a filling and protective material to enhance comfort and safety. It is commonly used in the production of furniture, mattresses, and other products.

Construction Industry Applications

In construction, orange open cell sponge is used for sealing and isolation purposes. It effectively prevents air and moisture infiltration, improving the energy efficiency of buildings. Its pressure resistance and anti-aging properties also make it reliable for long-term use in buildings.

Automotive and Transportation

Orange open cell sponge is widely used in the automotive, railway, and aerospace industries for vibration isolation and sealing. It effectively reduces vibrations and noise, improving vehicle comfort.

Refrigeration and Air Conditioning Equipment

In refrigeration and air conditioning equipment, orange open cell sponge is used as a sealing and insulation material. Its excellent thermal insulation properties help maintain the efficiency of equipment while reducing energy loss.

Electrical and Electronic Applications

In electrical and electronic devices, orange open cell sponge is used to prevent external interference with electronic components. It effectively blocks moisture, dust, and other contaminants, ensuring the long-term stable operation of the equipment.

FAQ

What are the main features of orange open cell sponge?

Orange open cell sponge has excellent water absorption, elasticity, high-temperature resistance, and wear resistance, making it ideal for applications in packaging, sealing, and protection.

Which industries is this sponge suitable for?

It is widely used in packaging, transportation, automotive, construction, electrical, electronic, and physical therapy industries.

How is the high-temperature performance of this sponge?

Orange open cell sponge maintains good stability at temperatures up to 80°C, making it suitable for high-temperature sealing and protection needs.

What standards does this sponge meet?

Orange open cell sponge complies with FDA 21 CFR 177.2600 standards, making it safe for food contact applications.

What are the different densities available for this sponge?

Orange open cell sponge comes in densities ranging from 160 kg/m³ to 500 kg/m³, allowing customers to choose the best density for their specific needs.

Conclusion

With its outstanding physical properties, especially its water absorption, high-temperature resistance, and anti-aging qualities, orange open cell sponge is widely used in multiple industries. Its customizability, flexibility, and broad working temperature range make it an ideal choice for a variety of applications, including industrial sealing, packaging protection, and more. As technology advances, the applications of orange open cell sponge will continue to expand, making it an essential material for diverse industries.

| DENSITY | PORE | SIZE | WEIGHT |

|---|

| 500 Kg/m3 | 60 – 300 /cm | 1400 ± 10mm | 37kg |

| 350 Kg/m3 | 60 – 300 /cm | 1380 ± 55mm | 30kg |

| 300 Kg/m3 | 60 – 300 /cm | 1380 ± 55mm | 32kg |

| 270 Kg/m3 | 60 – 300 /cm | 1380 ± 55mm | 30kg |

| 270 Kg/m3 | 60 – 300 /cm | 1270 ± 55mm | 30kg |

| 250 Kg/m3 | 60 – 300 /cm | 1820 ± 75mm | 42kg |

| 250 Kg/m3 | 25 – 120 /cm | 1820 ± 75mm | 42kg |

| 200 Kg/m3 | 60 – 300 /cm | 2120 ± 75mm | 40kg |

| 200 Kg/m3 | 25 – 120 /cm | 2120 ± 75mm | 40kg |

| 200 Kg/m3 | 25 – 120 /cm | 1270 ± 75mm | 36kg |

| 160 Kg/m3 | 60 – 300 /cm | 2120 ± 75mm | 35kg |

| 160 Kg/m3 | 25 – 120 /cm | 2120 ± 75mm | 37kg |

| 160 Kg/m3 | 10 – 40 /cm | 2120 ± 75mm | 35kg |

| 160 Kg/m3 | 10 – 40 /cm | 1270 ± 55mm | 26kg |

| 130 Kg/m3 | 60 – 300 /cm | 2120 ± 75mm | 30kg |