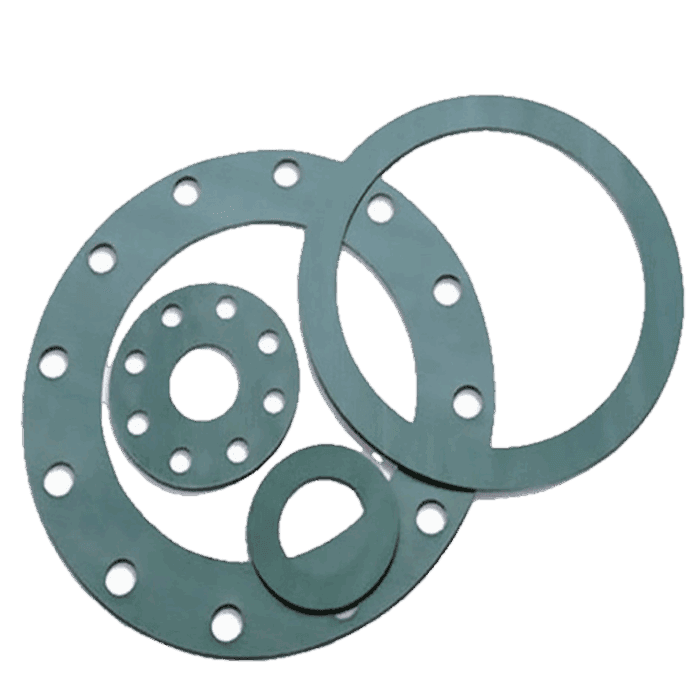

Flexseals Asbestos-Free Gaskets — A Comprehensive Analysis

Flexseals asbestos-free gaskets are a highly versatile sealing solution widely used in various high-temperature, high-pressure, and high-chemical environments. These gaskets, free from asbestos, use advanced materials and manufacturing processes to provide reliable sealing performance across industries such as oil and gas, chemical, energy, and marine. In this article, we will thoroughly explore the features, material grades, application ranges, and performance of Flexseals asbestos-free gaskets.

Key Features

1.High-Quality Asbestos-Free Materials

Flexseals asbestos-free gaskets are made of high-quality materials that are not only safe for human contact but also exhibit excellent physical and chemical properties. Asbestos has been gradually phased out in industrial applications, especially in sealing products. By using asbestos-free materials, Flexseals gaskets ensure a safer and more eco-friendly solution.

2.Custom Manufacturing Service

Every industry and application has unique requirements, which is why Flexseals offers a custom manufacturing service to produce gaskets in various sizes, shapes, and thicknesses. Whether for small-batch production or large-scale manufacturing, Flexseals can meet the high-quality demands of its customers.

3.Wide Working Temperature Range

Flexseals asbestos-free gaskets perform excellently even in extreme temperature conditions. With different grades of gaskets available, they can withstand temperatures ranging from ambient to as high as 330°C. This broad temperature range makes them highly adaptable for use in steam, hot gas, or chemical reaction environments.

4.High Durability

These gaskets are made from highly durable materials that can maintain their sealing performance even under prolonged compression and high pressure. Flexseals gaskets exhibit excellent durability, which extends their service life in extreme operational conditions.

5.Excellent Compressive Strength

Flexseals asbestos-free gaskets can withstand high pressure while maintaining a stable sealing effect. Whether in static or dynamic sealing environments, these gaskets provide superior compressive strength, ensuring consistent performance over time.

6.Good Chemical Resistance

Flexseals asbestos-free gaskets offer excellent chemical resistance, making them suitable for environments exposed to oils, fuels, acids, and alkalis. They are ideal for chemical plants, oil fields, and other applications where chemical resistance is critical.

7.Good Recovery Performance

Flexseals asbestos-free gaskets exhibit excellent recovery performance. After prolonged use or compression, these gaskets can return to their original shape, ensuring long-term stability and sealing efficiency.

8.Wide Range of Applications

Flexseals asbestos-free gaskets are highly versatile and can be used in a wide range of industries, including oil and gas, chemical, marine, energy, automotive, aerospace, mining, and water treatment industries. They provide highly efficient and reliable sealing solutions for static and dynamic sealing needs.

Flexseals Material Grades

The Flexseals asbestos-free gasket series includes several material grades designed to meet various application needs. Depending on the working environment, users can choose different material grades to suit specific requirements. Below are the common material grades and their performance specifications:

1. Flexseals 163 (Green)

•Maximum Working Temperature: 140°C (Continuous) / 210°C (Intermittent)

•Maximum Working Pressure: 20 Bar

•Characteristics: Suitable for low-pressure applications, offering good resistance to oil, fuel, and common chemicals. Ideal for applications that do not require high-temperature resistance.

2. Flexseals 330 (White)

•Maximum Working Temperature: 330°C

•Maximum Working Pressure: 90 Bar

•Characteristics: This high-quality grade gasket features outstanding high-temperature resistance, oil, and fuel resistance. Suitable for high-temperature and high-pressure applications.

Applicable Fields

Flexseals asbestos-free gaskets have extensive applications across multiple industries. The main application areas include, but are not limited to:

•Petrochemical: Used for sealing applications in oil refining, natural gas extraction, and chemical production.

•Oil and Gas: Applied for pipeline, pump, and equipment sealing, especially in high-temperature and high-pressure environments.

•Marine: Used in ships, platforms, and offshore equipment, offering corrosion resistance and seawater tolerance.

•Power Generation: Widely used in power plants for equipment sealing, ensuring equipment stability and long-term operation.

•Mining: Seals for mining equipment in extreme operational conditions.

•Aerospace: Provides reliable sealing performance for aerospace and satellite components.

•Automotive: Used for engine, exhaust systems, and other automotive components to ensure sealing and heat resistance.

•Water Treatment: Used in water treatment plants to maintain sealing integrity and prevent leaks.

Conclusion

Flexseals asbestos-free gaskets are a high-performance, eco-friendly, and safe sealing material that provides excellent temperature, pressure, and chemical resistance. They are widely used across a variety of industries. Not only do these gaskets offer excellent sealing performance, but they also excel in durability, recovery performance, and stability under various working conditions. With custom manufacturing capabilities, Flexseals can produce gaskets in various sizes, shapes, and materials to meet the unique requirements of customers, ensuring the best sealing solution for any application.