Custom Silicone Molding

Product Overview

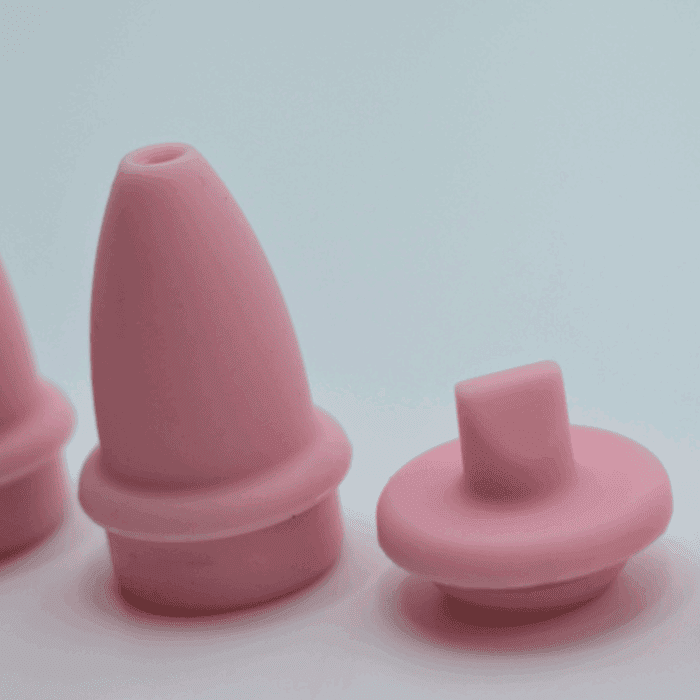

Custom silicone molding is a key aspect of modern manufacturing processes, especially in industries where high performance, precision, and durability are critical. Silicone rubber, known for its remarkable properties, is commonly used in a variety of molded applications, including seals, gaskets, keyboard components, bellows, covers, instrument caps, and more. As one of the leading companies in the field, Nanjing Yuhang Rubber specializes in providing high-quality custom silicone molding solutions that cater to the unique demands of our clients.

Key Features of Custom Silicone Molding

1.Tailored to Your Specific Requirements

At Nanjing Yuhang Rubber, we understand that each project has its unique requirements. Our custom silicone molding services allow you to design and create rubber components that meet your precise specifications. Whether you need a specific size, shape, color, or material type, we can produce silicone components that are customized to fit your exact needs.

2.Advanced Manufacturing Processes

We utilize cutting-edge manufacturing techniques, such as compression and transfer molding, to produce silicone rubber products with precision. These methods ensure that the final product meets the highest standards of quality and durability. Our expert team utilizes the latest technological advances to deliver products that exceed expectations.

3.High Precision and Tight Tolerances

With a focus on quality and precision, our silicone molding products are made with high accuracy and strict tolerances. We are capable of producing custom parts with tolerances as tight as 0.003 inches, ensuring that the finished product meets your specifications. This level of precision is vital in applications where performance and consistency are crucial.

4.Rapid Turnaround Time

We understand the importance of meeting deadlines in the fast-paced world of manufacturing. Therefore, we pride ourselves on our quick turnaround times. Whether you need a small batch or a large volume, our advanced production processes enable us to deliver your custom silicone components within a short time frame.

5.Wide Range of Silicone Rubber Options

We offer a diverse selection of silicone rubbers, which are tailored to specific industries and applications. Our range includes options that meet various material certifications such as FDA, WRAS, and UL. This ensures that the molded silicone products comply with global industry standards and regulations, making them suitable for a variety of critical applications.

6.Versatile Applications

Our custom silicone molds can be used across a wide array of industries. Silicone rubber is known for its high-temperature resistance, weatherability, water resistance, and versatility, making it ideal for applications in medical devices, food processing, automotive, construction, electronics, and more. Whether you need molded seals, gaskets, or custom extrusions, we can produce parts that meet your unique requirements.

7.Unique Material Properties

Silicone rubber exhibits unique material properties that make it an ideal choice for a variety of applications. It has excellent resistance to high and low temperatures (ranging from -100°C to +300°C), making it suitable for applications in both extreme hot and cold conditions. Additionally, it is highly resistant to UV light, ozone, and aging, which makes it ideal for outdoor and high-durability applications.

The flexibility of silicone rubber is also a key feature. It can maintain its shape and functionality even in harsh environments. Moreover, it has a high degree of elasticity, providing long-lasting performance in applications that require continuous motion, stretching, or compression.

8.Shape Memory and Flexibility

One of the remarkable properties of silicone rubber is its excellent “shape memory.” This feature ensures that silicone products can maintain their original shape, even after being compressed or deformed under pressure. This makes silicone rubber especially useful in applications requiring a reliable and consistent seal over time, as it returns to its original form after being pressed or squeezed.

9.Comprehensive Product Range

9.Comprehensive Product Range

At Nanjing Yuhang Rubber, we offer a wide range of custom silicone molded products. These include:

•Silicone gaskets and seals

•Silicone diaphragms

•Silicone flame-retardant seals

•Conductive silicone gaskets

•Silicone edge protectors

•Silicone extrusions: A, D, e, h, L, P, T, U, V, and Y profiles

•Silicone wiper blades

•Silicone lips

Whether you require standard gaskets or custom shapes, we can produce the parts you need for various applications in industries such as automotive, construction, healthcare, and more.

Applications of Custom Silicone Molding

Custom silicone molded products serve a wide range of applications across multiple industries. Their ability to perform in challenging environments, combined with their flexibility and durability, makes them ideal for a variety of demanding uses. Some of the key applications include:

•Static and Radial Seals: Silicone molded gaskets are commonly used to provide static and radial seals for equipment such as pipelines, liquid or gas transport systems, and more.

•HVAC Seals: Silicone seals are commonly used in heating, ventilation, and air conditioning systems to prevent air leakage, ensuring efficient operation of HVAC systems.

•Water Well Gaskets: Silicone gaskets are ideal for sealing water wells, as they can withstand harsh environmental conditions and ensure long-lasting seal integrity.

•Vacuum Sweeper Belts: Silicone gaskets are widely used in vacuum cleaner belts, providing excellent sealing and durability to ensure smooth and reliable performance.

•Non-Conductive Insulation Gaskets: Silicone gaskets are often used in electrical and electronic equipment as non-conductive insulation, ensuring safety and protection for electrical components.

•Food-Grade Gaskets: For applications in the food industry, silicone gaskets made from FDA-approved materials ensure safe food contact and maintain product quality.

•Filter Gaskets: Silicone gaskets are used in automotive, industrial, and household filters to provide effective sealing and filtration performance.

•Power Transformer Gaskets: Silicone gaskets are used in power transformers to ensure safety and stability under high-voltage conditions.

Material Choices for Custom Silicone Molding

We offer a range of silicone materials for custom molding, including options with various hardness, densities, and colors. The following materials are commonly used in our custom molding process:

•Butyl Rubber: Known for excellent sealing performance and aging resistance, commonly used in the power and chemical industries.

•EPDM (Ethylene Propylene Diene Monomer): Offers excellent weather and ozone resistance, ideal for outdoor and extreme conditions.

•Natural Rubber: Provides good elasticity and wear resistance, suitable for general industrial sealing applications.

•Neoprene Rubber: Offers good oil and chemical resistance, suitable for chemical environments.

•Nitrile Rubber: Excellent oil and solvent resistance, widely used in automotive, petroleum, and chemical industries.

•Silicone Rubber: Ideal for high-temperature applications, widely used in medical and food industries.

•Fluorocarbon Rubber (FKM): Known for high-temperature and chemical resistance, suitable for demanding industrial environments.

•Solid and Sponge Rubber Materials: We offer a variety of solid and sponge rubber options depending on the specific sealing requirements.

Customization Services

At Nanjing Yuhang Rubber, we provide highly customizable lathe-cut gaskets and seals. You can select the materials, thickness, size, and shape to suit your exact requirements. Whether you need high-volume production or small-scale custom runs, we can meet your needs. Additionally, we offer various surface treatments, adhesive backings, and custom formulations to ensure each gasket perfectly matches your application.

Conclusion

Lathe-cut gaskets and seals play a crucial role in many industries. With their high precision, cost-efficiency, and flexible customization, lathe-cut gaskets have become the ideal choice for sealing in numerous industrial applications. Nanjing Yuhang Rubber, with its extensive experience and professional expertise, offers high-quality, reliable lathe-cut gaskets. Whether you need materials with high-temperature resistance, aging resistance, or corrosion resistance, Nanjing Yuhang Rubber provides the best solutions for your needs.

9.Comprehensive Product Range

9.Comprehensive Product Range