Industrial Sponge: High-Performance Open-Cell Sponge Solutions

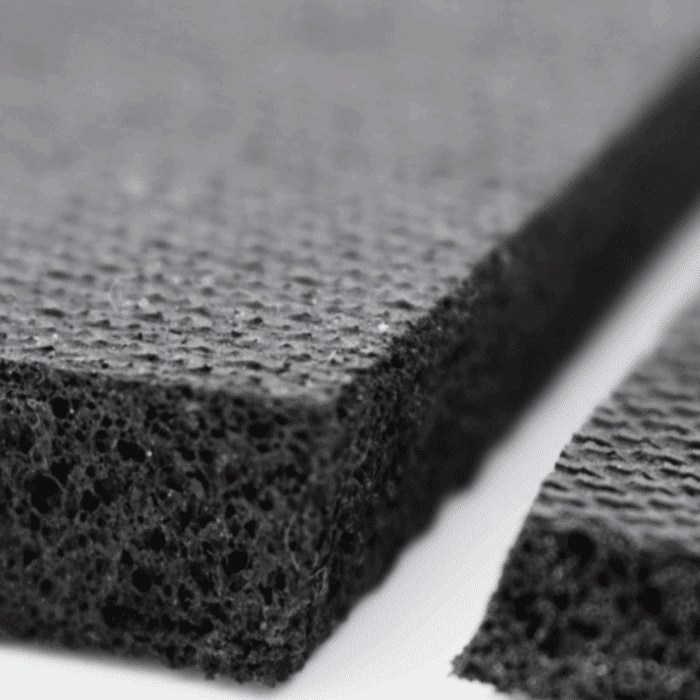

Open-cell industrial sponge, made from high-quality natural rubber material, is a versatile solution used across various industries. With its unique open-cell structure, excellent compression recovery, and outstanding weather resistance, it has become an ideal choice for industrial sealing, shock absorption, and protection in numerous applications.

Key Features of Open-Cell Industrial Sponge

1. Unique Open-Cell Structure

The open-cell design is one of the most notable features of this sponge. It provides exceptional flexibility and adaptability, allowing it to form effective seals on uneven or complex surfaces. Compared to closed-cell sponges, the interconnected pores of open-cell sponges enable gas or liquid absorption and circulation, making them particularly useful in ventilation, drainage, or soundproofing applications.

For example, in specialized construction projects, open-cell sponges are often used as solutions for vibration dampening and noise insulation, effectively reducing mechanical vibrations and noise pollution in offices, theaters, and sound rooms.

2. Excellent Compression Recovery

Open-cell industrial sponge exhibits outstanding compression recovery, meaning it can quickly regain its original shape after being compressed for long periods. This property is crucial for packaging, cushioning, and sealing applications that require repeated use. Our open-cell sponge ensures effective sealing and protection, prolonging its service life.

For instance, as a packaging material, it safeguards products during transportation and retains its cushioning properties over time, ensuring reliable protection.

3. Superior Weather and Ozone Resistance

As a high-performance natural rubber material, open-cell industrial sponge boasts excellent weather and ozone resistance. Unlike many rubber materials that become brittle or degrade under exposure to UV rays, ozone, and harsh environmental factors, our open-cell sponge is designed to withstand such challenges. It maintains peak performance in extreme temperatures, high humidity, or outdoor conditions, reducing maintenance frequency.

This weather resistance makes it ideal for long-term outdoor applications, such as sealing building exteriors or protecting industrial equipment components.

4. Various Density and Thickness Options

We offer open-cell industrial sponge in different densities, with a standard density of 380 kg/m³. Thickness options range from 3mm to 25mm, and custom dimensions are available upon request. Customers can choose the right density and thickness for specific pressures, temperatures, and environmental conditions.

In addition to standard sizes, we provide customized forms, including rolls, sheets, strips, and CNC-cut gaskets, ensuring our sponge can meet diverse application needs and simplify installation and maintenance.

5. Durability and Cost-Effectiveness

The durability of open-cell industrial sponge makes it a popular choice in industrial applications. Its elasticity and physical strength allow it to withstand repeated loading and deformation, making it ideal for applications requiring frequent impact and pressure absorption. Whether used as protective packaging or sealing and vibration-dampening material in construction, it significantly enhances material lifespan.

Moreover, its physical strength and durability make it suitable for demanding industries such as electronics, automotive, and aerospace, where it improves product reliability and performance.

Applications of Open-Cell Industrial Sponge

1. Construction and Noise Insulation

Open-cell industrial sponge is widely used in the construction industry for sealing and noise insulation. Its excellent vibration-dampening properties make it a preferred choice for sealing building exteriors, soundproof panels, and mechanical equipment.

2. Packaging and Protection

This sponge is an ideal packaging material, providing effective shock absorption during transportation and preventing product damage. It is commonly used to protect precision instruments and electronic devices.

3. Machinery and Automotive Manufacturing

In machinery and automotive industries, open-cell sponge serves as a shock-absorbing material, reducing equipment vibration and noise, and enhancing equipment stability and lifespan.

4. Water Treatment and Air Filtration

In water treatment and air purification systems, open-cell sponge performs as a sealing and filtration material, effectively blocking impurities and contaminants, ensuring efficient operation.

5. Medical Equipment and Home Appliances

Open-cell sponge is also utilized in medical equipment and home appliances, offering reliable sealing and cushioning to meet high precision and cleanliness requirements.

Customization and Material Options

1. Wide Range of Materials

We offer various high-performance materials, including natural rubber, EPDM, silicone rubber, neoprene, and more, catering to different temperature, chemical, and application requirements.

2. Flexible Customization

Nanjing Yuhang Rubber provides highly customizable solutions for open-cell industrial sponges. From standard rolls and sheets to special shapes such as CNC-cut gaskets, we cater to your specific needs.

3. Surface Treatment and Backing Options

We offer additional options such as surface treatment and adhesive backing, ensuring the sponge material adapts perfectly to diverse use cases.

Frequently Asked Questions (FAQ)

Q1: What temperature range can open-cell industrial sponge withstand?

The working temperature typically ranges from -40°C to +100°C, with certain materials capable of withstanding higher or lower temperatures.

Q2: Is open-cell sponge suitable for humid environments?

Yes, its breathability and drainage capabilities make it ideal for moisture-sensitive scenarios, such as HVAC systems or outdoor equipment.

Q3: Can the thickness and density of the sponge be customized?

Absolutely. We offer thicknesses from 3mm to 25mm and various densities to meet specific customer needs.

Q4: What are the primary advantages of open-cell sponge?

Key benefits include excellent compression recovery, weather resistance, adaptability, and cost-efficiency.

Q5: Is the open-cell sponge environmentally friendly?

Yes, our sponges are made from eco-friendly materials that meet international environmental standards, making them suitable for industries with high environmental requirements.

Conclusion

Open-cell industrial sponge stands out as a versatile material, offering unique properties such as exceptional compression recovery, ozone resistance, weather durability, and customization. Whether used as packaging, sealing, or vibration-dampening material, it meets the highest standards in various industries.

Nanjing Yuhang Rubber ensures high-quality open-cell industrial sponges and tailored solutions to address diverse customer needs. From construction and machinery to water treatment and more, our products deliver reliable performance and exceptional value.