Title

Custom Rubber Extrusions|High-Performance Industrial Rubber Profiles

Meta Description

Premium custom rubber extrusions with diverse material options and advanced finishing services. Ideal for industrial, automotive, construction, and medical applications.

Product Description

Custom Rubber Extrusions – Versatile Solutions for Every Industry

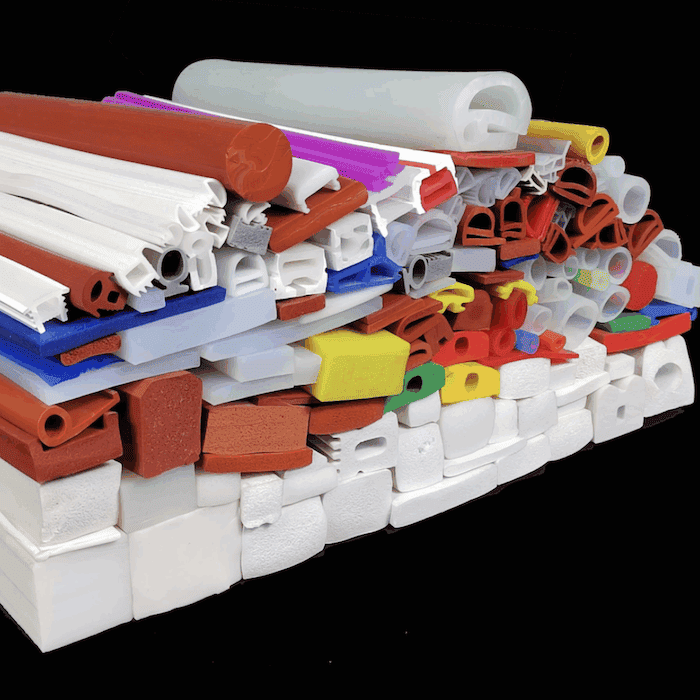

Custom rubber extrusions are high-performance solutions tailored to meet the unique needs of various industries. Whether for sealing, protection, vibration damping, or fluid transfer, our extrusions deliver exceptional performance and a wide range of material and processing options to tackle complex application scenarios.

Key Features & Benefits

1. Diverse Material Options

From natural rubber to advanced composites, including EPDM, silicone, TPE, and neoprene, to meet diverse environmental demands.

2. High-Quality Compounds

Premium materials are rigorously selected to ensure excellent chemical, mechanical, and durability properties.

3. Wide Hardness Range

Customizable Shore hardness from 30° to 90° to meet sealing or support requirements.

4. Comprehensive Processing Services

Options include welding, cutting, drilling, ink marking, and lubricant coatings to support complex designs.

5. RAL Color Matching

Customizable colors to align with brand identity or specific visibility needs.

6. Special Certifications

Materials compliant with FDA approvals, flame-retardant, or anti-static requirements to meet regulatory and industry standards.

7. Flexible Material Combinations

Choose from solid rubber, sponge rubber, or hybrid materials for versatile applications.

8. Fully Customized Solutions

Tailored designs and production based on your application, design, and performance requirements.

Design & Manufacturing Capabilities

With over 100 years of expertise, our custom rubber extrusions are widely used in construction, automotive, medical, and industrial applications. Utilizing modern manufacturing technologies and precise process controls, we ensure consistent quality and high-performance products.

Rubber welding technology creates seamless profiles for demanding sealing applications, eliminating weaknesses from adhesive joints. Additional options include tensile-reinforced profiles and self-adhesive backings for easier installation and enhanced performance.

Finishing Services

• Welding Technology: Achieves complex geometries and seamless joints.

• Precision Cutting & Drilling: Meets tight tolerances, with lengths as short as 10mm.

• Lubricant Coatings: Reduces friction and simplifies assembly.

• Mirror Welding: Maintains flexibility and integrity for circular and frame profiles.

Material Options & Performance

1. EPDM

Excellent weather resistance for outdoor and extreme climate applications.

2. Silicone

FDA-grade material with outstanding high-temperature resistance, up to 300°C.

3. Neoprene

Ideal for oil and abrasion resistance in industrial and automotive use.

4. TPE

Combines rubber flexibility with plastic durability, ideal for premium sealing and decorative applications.

Applications

• Construction & Engineering: Door and window seals, waterproofing strips, and pipe protection.

• Automotive: Sealing profiles, vibration damping, and fender components.

• Food & Medical: FDA-certified seals and tubing for hygienic environments.

• Industrial Manufacturing: Mechanical protection, vibration pads, and high-pressure seals.

Specifications & Custom Options

• Hardness Range: 30°-90° Shore A.

• Color Options: Standard black, RAL-matched, or custom colors.

• Thickness & Dimensions: From precision seals to large industrial profiles.

• Processing Services: Welding, drilling, cutting, and surface treatments.

FAQs

1. What industries can benefit from rubber extrusions?

Industries include construction, automotive, food, medical, and industrial manufacturing.

2. What material options are available?

Materials include EPDM, silicone, TPE, neoprene, and more.

3. Can you customize colors?

Yes, we offer RAL color matching and custom options based on client needs.

4. What processing services do you offer?

We provide welding, cutting, drilling, and surface treatments.

5. Are certified materials available?

Yes, we offer materials compliant with FDA, flame-retardant, and anti-static standards.

Conclusion

Custom rubber extrusions are the ultimate choice for sealing, protection, and vibration damping needs. Their flexible designs, superior performance, and advanced processing services make them highly reliable solutions across diverse applications. Contact our expert team today for more information or to discuss your customization needs.