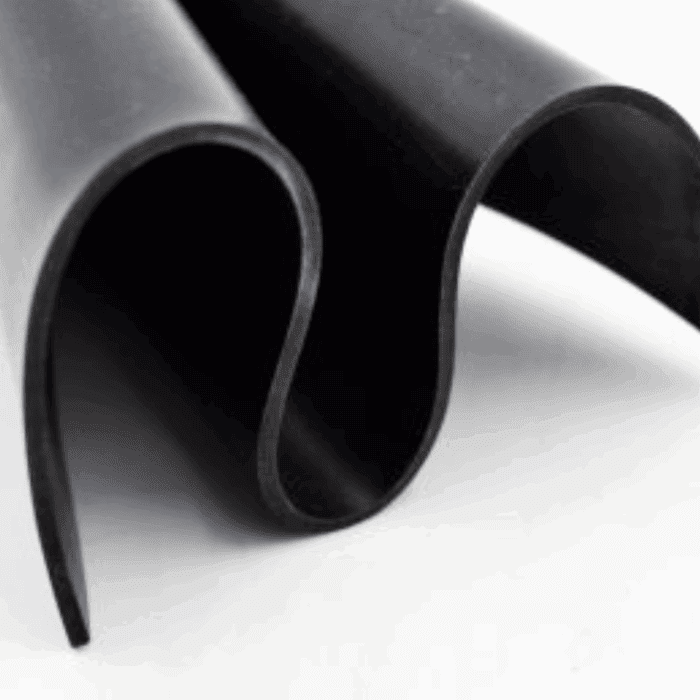

Hydrogenated Nitrile Rubber Film | Comprehensive High-Performance HNBR Solution

Hydrogenated Nitrile Rubber (HNBR) film is an advanced, high-performance material offering exceptional resistance to oil, fuel, and chemicals, combined with superior physical strength. This material is ideal for the petroleum, fuel processing, and transportation industries, as well as various industrial applications.

Key Features and Benefits

1. Outstanding Oil Resistance

Suitable for prolonged contact with engine oil, gasoline, lubricants, and vegetable oils without compromising material integrity.

2. Chemical and Solvent Resistance

Exhibits excellent resistance to solvents, diluted acids, and concentrated acids, making it ideal for harsh chemical environments.

3. Wide Temperature Range Adaptability

Performs reliably in extreme temperatures ranging from -40°C to +150°C.

4. Superior Physical Properties

High tensile strength and tear resistance ensure durability and reliability.

5. Variety of Thickness Options

Available in thicknesses from 0.5 mm to 50 mm, accommodating various application needs.

6. Versatile and Durable

Suitable for nearly all petroleum, natural gas, and industrial manufacturing applications.

7. Eco-Friendly and Compliant

Meets REACH, RoHS, PAH, and CE standards, ensuring environmental friendliness and safety compliance.

Product Description

Hydrogenated Nitrile Rubber (HNBR) film is engineered by introducing hydrogen into the molecular structure of nitrile rubber, significantly enhancing resistance to oils, fuels, and chemicals while improving physical strength. This modification makes the material highly suitable for demanding environments.

Available in various thicknesses (0.5 mm to 50 mm), the material supports multiple processing forms, including rolls, strips, gaskets, and custom shapes. Its superior chemical and physical properties make it ideal for applications in transportation, manufacturing, and fuel processing systems, particularly for fuel system seals, oil well equipment, and high-pressure diaphragms.

Potential Application Areas

1. Petroleum and Natural Gas Industry

Used for fuel system seals, accumulator bladders, and oil well seals.

2. Transportation Sector

Provides reliable sealing solutions for environments in contact with fuels and lubricants.

3. Manufacturing

Applied in industrial equipment as sealing strips, O-rings, and protective gaskets.

4. Chemical Processing

Suitable for laboratory and industrial chemical applications due to resistance to solvents and acids.

5. Diaphragm and Gasket Manufacturing

High tensile and tear strength make it ideal for high-pressure seals and diaphragms.

6. Eco-Friendly Energy Applications

Performs reliably in environments with metallic sludge and highly contaminated oils.

Specifications and Custom Options

• Thickness: 0.5 mm to 50 mm

• Width: Standard or custom sizes

• Hardness (Shore A): 70°±5

• Material: Hydrogenated Nitrile Rubber (HNBR)

• Color: Black

• Processing Forms: Rolls, strips, gaskets, O-rings

Product Advantages

1. Wide Applicability

Suitable for petroleum, transportation, manufacturing, and chemical sectors.

2. High-Performance Material

Exceptional oil and fuel resistance, designed for demanding environments.

3. Eco-Friendly and Compliant

Adheres to international environmental standards, ensuring green production.

4. Flexible Processing and Customization

Offers various thicknesses, widths, and shapes to meet specific requirements.

5. Superior Physical Strength

High tensile and tear resistance ensures long-term durability and reliability.

Frequently Asked Questions (FAQ)

1. What is the temperature range for HNBR?

It can operate reliably in environments from -40°C to +150°C.

2. Is HNBR certified for food safety?

It is primarily designed for industrial and chemical environments and is not certified for food contact.

3. Does it support custom shapes?

Yes, we offer customization for gaskets, O-rings, and strips.

4. Can it handle prolonged fuel exposure?

Absolutely, HNBR is specifically engineered for oil and fuel resistance in long-term applications.

5. What thickness options are available?

Thicknesses range from 0.5 mm to 50 mm, depending on the application.

6. What are the typical application areas for HNBR?

It is used in petroleum equipment seals, fuel systems in transportation, and chemical diaphragm manufacturing.

7. Does it comply with environmental standards?

Yes, it meets REACH, RoHS, PAH, and CE standards.

8. How should HNBR film be stored?

Store in a cool, dry place away from direct sunlight, high temperatures, and humidity.

Hydrogenated Nitrile Rubber (HNBR) film is the perfect solution for demanding industrial applications. Contact us to learn more or request customized services.

STANDARD ROLL SIZES

WEIGHT KG/M2

PROPERTIES

VALUES

|

|

|

|

1mm x 1.4m x 20m | 1.20 | Compound | HNBR |

2mm x 1.4m x 20m | 2.40 | Density (Specific Gravity) | 1.20 g/cm2 |

3mm x 1.4m x 10m | 3.60 | Tensile Strength | 100 kg/cm2 |

5mm x 1.4m x 10m | 6.00 | Elongation at Break | 200% |

6mm x 1.4m x 10m | 7.20 | Tear Strength | 45 kg/cm |

|

| Compression Set (24hrs @ 70°C ) | 50% |

|

| Minimum Temperature | -30°C |

|

| Maximum Temperature | +150°C |